MIOConsole Overview

MIO Console for 2d interfaces

MIO Console is the nerve center of your Mobile I/O. Functioning as a standalone application, MIO Console provides full control of every aspect of Mobile I/O. The console software allows you to rapidly and easily adjust all of the Analog Input and Output channel parameters, system sample rate, Digital I/O source, and system clock source.

In order to simplify work flow and optimize the extent of system control, MIO Console supports comprehensive preset management on both a global and individual control level.

The preset management popup controls within MIO Console allow you to configure various aspects of Mobile I/O and save that configuration information for later recall. Various applications include storing routing configurations for monitor setups, mixer configurations for stem and scene recall, and storing analog level standards for interfacing with external gear and managing different mastering standards.

Global configuration snapshots allow you to save each and every aspect of Mobile I/O's configuration for later, total instant recall. This is useful for preconfiguring Mobile I/O and bringing back the configuration once at the gig, managing separate location setups, or for saving complex studio routing setups for quick changeover.

MIO Console Overview

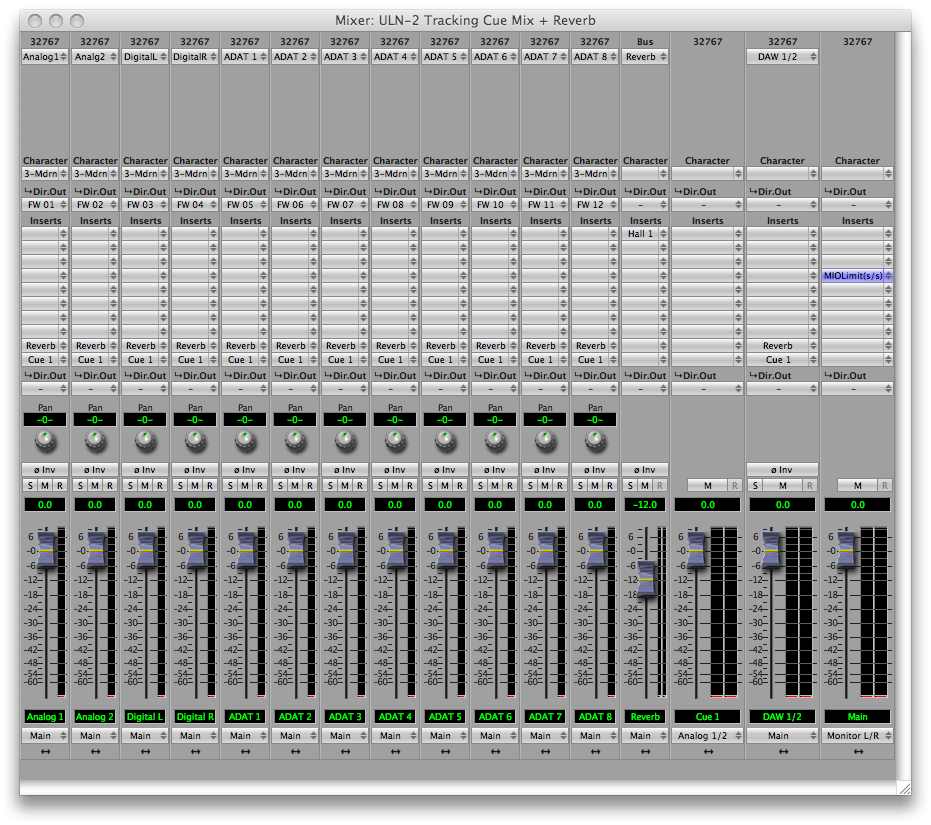

The MIO Console application has two main windows:

- The Console window, which is used for box-specific hardware settings.

- The Mixer window, which provides a unified view of whatever channels you want to use from all connected boxes.

Let's start by looking at the Console window, since there are many important hardware settings in this area. Then, we'll look at the Mixer window, where you define the flexible environment that will be your work surface.

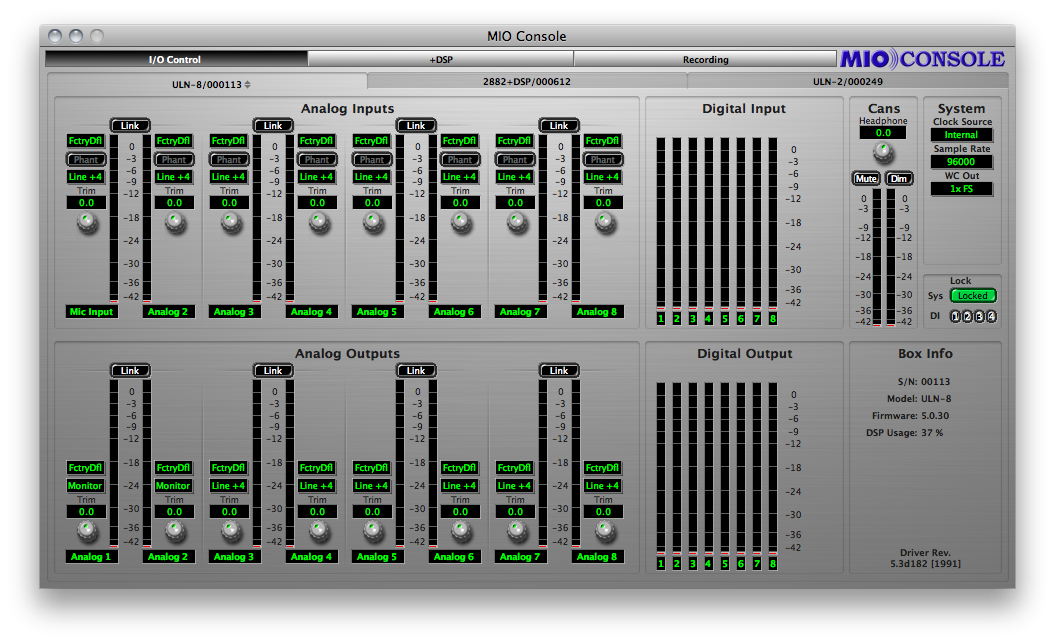

The Console Window

The MIO Console window has a view panel selector bar that runs along the top of the window. This bar indicates which of the console view panels is currently active. You can tell which panel is active because the button in the bar is “pushed in.” To switch to one of the other panels, simply click on the name of the panel you want to use. The view will change instantly to the one that you have selected.

Under the view panel selector bar is the currently selected view panel. You control the various aspects of the box with the controls in each view. MIO Console has five main panels:

- I/O Panel

- +DSP Panel

- Record Panel

The +DSP panel allows you to see (but not modify) what's going on "behind the scenes" in the DSP of your interfaces. This area is known as the "Übergraph".

The Record Panel is our built-in multitrack recording utility. Documentation on the RP can be found in the Record Panel documentation.

I/O Panel

This panel provides full control and metering of all of the analog I/O that the box provides. The top half of the view is dedicated to inputs and the bottom half is dedicated to outputs. You access this panel by clicking on the “I/O Control” button of the view panel selector bar.

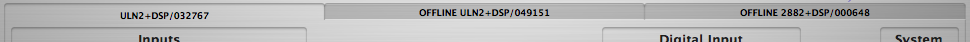

Box Tabs

At the top of the panel are Box Tabs — one for each box known to the system. You choose which box you are controlling by clicking on the desired box tab. Boxes can be either Online or Offline. If a box is not connected to the computer but it is known to MIO Console, it will be listed as Offline in MIO Console. You can modify the configuration of an Offline box, and that configuration can be saved, but, of course, the changes will not control the Hardware until it is reconnected to the computer.

MIO Console maintains information about the state of your system persistently. The boxes that have been attached to the computer will be remembered, and their presence in the system can be maintained indefinitely by either the saved system state (saved in your Preferences to maintain the state of the system between launches of MIO Console) or by you explicitly saving the state of the console into a file for later recall (or into a ConsoleConnect host’s session file). In any case, it is possible to have Offline boxes in your system state that refer to a box that you are no longer using. MIO Console provides commands to remove these boxes from the system state.

Each box tab provides a contextual menu that you can popup to apply commands to the specific box. Right-click or control-click the currently active box tab to reveal the popup menu:

This menu provides the following commands:

- Forget This Offline Box — this command will remove the box from the system state.

- Forget This Offline Box (and Delete From Mixer) — this command will remove the box from the system state and delete any channels associated with it from the Mixer.

- Forget All Offline Boxes — this command will remove all boxes that are offline from the system state.

- Forget All Offline Boxes (and Delete From Mixer) — this command will remove offline boxes from the system state and delete any channels associated with them from the Mixer.

- Identify Box — this command will cause a lightshow to appear on the front panel meters of the box associated with the tab. Use this command to identify which physical box is represented by the tab.

- Reset Box Output Channel Names — this command resets all of the user-specified names for output channels to the factory default settings for the hardware.

- Reset Box Input Channel Names — this command resets all of the user-specified names for input channels to the factory default settings for the hardware.

- Reset All Box Channel Names — this command resets all of the user-specified names for the I/O channels to the factory default settings for the hardware.

Front Panel Preferences

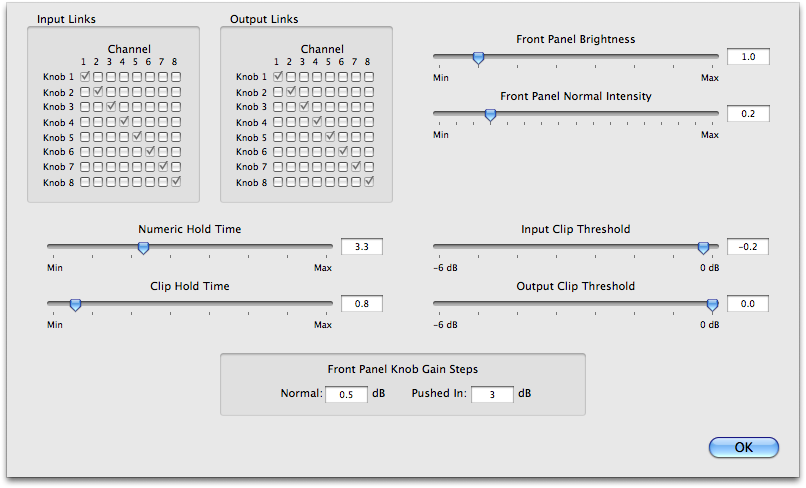

On the ULN-8, selecting "Front Panel Prefs…" will reveal the following sheet:

- Input Links matrix

Allows you to link input channel encoders (more info here). - Output Links matrix

Allows you to link output channel encoders (more info here). - Front Panel Brightness

Scales the brightness level of the front panel (more info here). - Front Panel Normal Intensity

Sets the maximum illumination level; the brightness scales to this point. - Numeric Hold Time

The time in seconds that the meters display numeric levels after adjusting an encoder. - Clip Hold Time

The time in seconds that the meter LEDs stay red after clipping occurs. - Input Clip Threshold

The input level at which a signal is considered clipped. - Output Clip Threshold

The output level at which a signal is considered clipped. - Front Panel Knob Gain Steps

Normal: The amount of gain change per encoder click when not pushed in.

Pushed In: The amount of gain change per encoder click when pushed in.

ANALOG INPUT CONTROL

For each analog input channel on the Mobile I/O, you will find a channel strip that contains:

- Parameter Popup control menu

Parameter Pop-up Menu

Parameter Pop-up Menu- The Parameter Popup control allows you to save, recall, and manage all of the parameters associated with the head amp of a channel strip in one place. The control is documented in detail here. All presets are automatically shared between all of the input channels.

- Phantom Power enable button

Phantom Power Button

Phantom Power Button- The Phantom Power enable button allows you to control whether or not +48v phantom power is applied to the input by the Mobile I/O. This button is only enabled if you have selected Mic or Mic/Pad as the input level standard. If you are using one of the other level standards, Phantom Power is automatically disabled. If you have enabled Phantom Power on this channel, the button will be illuminated bright red. In addition, the Mobile I/O front panel will illuminate the “Phantom” indicator if any of the input channels have Phantom Power enabled.

- Phantom power is appropriate for use with condenser microphones or other devices that can (and must) be powered by the preamp. Mobile I/O limits the amount of phantom power to 10mA per channel, preventing device damage due to shorts. Some (rare) microphones may require more power than is provided by 10mA; you will need an external power supply to power those mics.

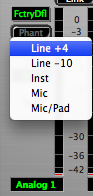

- Level Standard popup menu

Level Standard Pop-up Menu

Level Standard Pop-up Menu- This control allows you to select the input level and impedance characteristics for the input channel. The available choices are:

- Line +4 — This format supports input levels up to +26 dBu. The input impedance is approximately 10k, and the inline pad is engaged. Phantom power is not available. This format is appropriate for interfacing with professional audio equipment.

- Line -10 — This format supports input levels up to +26 dBu. The input impedance is approximately 10k, and the inline pad is engaged. Phantom power is not available. This format is appropriate for interfacing with prosumer and consumer audio equipment.

- Inst (Instrument) — This format supports input levels up to +6 dBu. The input impedance is approximately 200k, and the inline pad is not engaged. Phantom power is not available. This format is appropriate for interfacing with high output impedance sources like guitar pickups.

- Mic — This format supports input levels up to +6 dBu. The input impedance is approximately 200k (12k with phantom power engaged) and the inline pad is not engaged. Phantom power is available. This format is appropriate for interfacing with dynamic and condenser microphones on low to mid level sources. You may find that for very low level sources, especially with low-sensitivity microphones, that your SNR improves if you take advantage of a high-quality external mic preamp. External preamps are recommended for certain types of recording and microphones, especially classical recording and ribbon mics.

- Mic/Pad — This format supports input levels up to +26 dBu. The input impedance is approximately 10k, (6k with phantom power engaged) , and the inline pad is not engaged. Phantom power is available. This format is appropriate for phantom powered condenser mics that put out near-line level signals (often the case when you are using condenser microphones on bass drums or other very loud sources).

- This control allows you to select the input level and impedance characteristics for the input channel. The available choices are:

- Gain Trim knob

Gain Trim KnobThe Gain Trim knob allows you to adjust the analog gain of the input stage over a 40dB range determined by the input standard that you have selected. The gain is indicated in dB relative to the nominal level of the input standard you have selected. The gain changes are smoother near the bottom of the scale, with the steps increasing in size as you reach the gain limit.

Gain Trim KnobThe Gain Trim knob allows you to adjust the analog gain of the input stage over a 40dB range determined by the input standard that you have selected. The gain is indicated in dB relative to the nominal level of the input standard you have selected. The gain changes are smoother near the bottom of the scale, with the steps increasing in size as you reach the gain limit. - Channel Label

Channel LabelThis simply labels which channel is associated with the channel strip. Click in the lable to edit the channel name.

Channel LabelThis simply labels which channel is associated with the channel strip. Click in the lable to edit the channel name. - Channel Level Meter

Channel Level Meter

Channel Level MeterThis is a peak reading, high-resolution, fast PPM meter. It shows the post converter level of the input signal of the associated channel.. The peak hold bar indicates the highest level seen on the channel since the last reset. You can reset the hold by clicking on the meter. These meters are simply high resolution versions of the meters shown on the front panel of the box – all the meter data is generated by the Mobile I/O hardware.

OPTIMIZING INPUT LEVELS

The Analog to Digital converters (ADC) in most devices function best when the peak level is around -6 dBFS (lowest distortion, best sound). This is true of the ADCs in Mobile I/O. Since you have full level control of the input with the gain trim knob, you will find that you get the best quality recordings if you try to set the nominal peak level of the input at about -6 dBFS. In addition to providing the best recording quality, it has the added benefit that you will be operating with an extra 6 dB of headroom before clipping. There is no drawback to optimizing your levels in this way, and plenty of benefit.

ANALOG INPUT CHANNEL LINK

In addition to the channel specific controls, each channel pair shares a Link button. When the Link button is engaged, changes made to one channel of the pair will automatically be applied to the other channel of the pair. This is very useful if you are miking with a stereo pair and need to maintain level balance between the two preamps -- with the Link button engaged, the balance is automatic and exact. When you enable the Link button, the control values for the odd channel in the pair will be copied to the even channel of the pair.

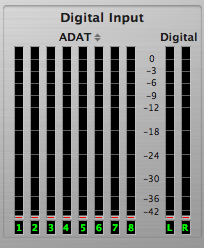

DIGITAL INPUT METERS

To the right of the Analog Input control section is the Digital Input Meter section. This group of meters provides level metering for all of the digital inputs on the Mobile I/O. These meters have the same response characteristics as the analog input meters and show you the audio activity on ADAT channels 1-8 and digital input channels 1-2, going from left to right on the 2882 and ULN-2. The ULN-8 digital input meters are for AES inputs 1-8, with no secondary meters.

Please note that when the box is clocking at 2x rates (88.2-96k), the ADAT input is not functional.

The label above the bank of 8 channel meters is a popup control that allows you to select between ADAT optical format and TOSLINK Optical SPDIF for the optical input connector. Click on the control to popup a menu to select between the different modes of operation. The mode is independently selectable for both the input and output.

If you have selected TOSLINK for either the input or output section, you will only see meters for channels 1+2 of the optical digital section. These correspond to the levels that are being transmitted or recieved in the optical SPDIF signal.

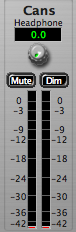

CANS CONTROLS

The next control block to the right is the Cans (Headphones) control section.

The Headphone level control knob provides about 40dB of analog gain control on the headphone output. The Mute and Dim buttons reflect the state of the hardware mute and dim controls for the front panel headphone output. Engaging one of these buttons will also engage the associated control on the hardware.

When the Mute function is engaged, the headphone output will be muted. When the Dim function is engaged, the headphone output will be padded by 18 dB. The meters in this section show the headphone output pre-mute/dim block.

SYSTEM CONTROLS

The System block provides controls that adjust various system level aspects of the Mobile I/O hardware:

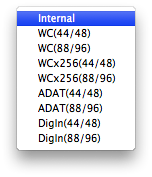

- The Clock Source popup menu controls the system clock source used by the hardware for digital synchronization and driving the converters:

Clock Source Pop-up Menu

Clock Source Pop-up Menu- Internal causes Mobile I/O to use its internal clock. You must select this if you want to set the sample rate from the Mobile I/O. If any other clock source has been selected, the console will not allow you to change the sample rate since the sample rate is determined by the external clock source.

- WC (44/48) directs Mobile I/O to clock off of an external Word Clock Source at single rate (e.g. fs = 32k-50k)

- WC (88/96) directs Mobile I/O to clock off of an external Word Clock Source at double rate (e.g. fs = 64k-100k)

- WCx256 (44/48) directs Mobile I/O to clock off of an external 256fs Clock Source at single rate (e.g. fs = 32k-50k)

- WCx256 (88/96) directs Mobile I/O to clock off of an external 256fs Clock Source at double rate (e.g. fs = 64k-100k)

- ADAT (44/48) directs Mobile I/O to clock off of the incoming ADAT stream and run at single rate. All 8 ADAT channels are available. You will generally want to select this source if you intend to use ADAT input.

- ADAT (88/96) directs Mobile I/O to clock off of the incoming ADAT stream and run at double rate. The bottom 4 ADAT channels are multiplexed over the lightpipe to provide 4 channels of double rate audio compatible with other SMUX and Alesis 96k ADAT devices. If you are using a device that provides 4 channels of 96k audio over ADAT optical, you will want to select this clock source.

- DigIn (44/48) directs Mobile I/O to clock off of the selected stereo digital input at single rate (e.g. fs = 32k-50k). This allows operation of the digital input without SRC, and from devices that must supply clock.

- DigIn (88/96) directs Mobile I/O to clock off of the selected stereo digital input at double rate (e.g. fs = 64k-100k). This allows operation of the digital input without SRC, and from devices that must supply clock.

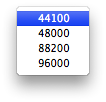

- The Sample Rate popup menu allows you to select the sample rate when you are using internal clock. The Mobile I/O must be running on internal clock for the Sample Rate popup menu to have any effect. If the Mobile I/O is running from an external clock source, you cannot select the sample rate since it is determined by the external clock source.

Sample Rate Popup Menu

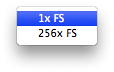

Sample Rate Popup Menu - The WC Out popup menu allows you to select the output clock signal the Mobile I/O generates on its WC Out BNC connector. The available choices are 1x and 256x. The 1x signal is appropriate for driving devices that accept a Word Clock signal. The 256x signal is appropriate for driving devices that accept 256x or SuperClock signals. Refer to the documentation for the external device to determine what is the most appropriate clock reference for it.

WC Out Popup

WC Out Popup - The DI Source popup menu allows you to select the active input for the digital input pair. The choices are AES and S/PDIF. This selector physically switches the input to the digital audio receiver between the RCA input and the XLR input.

DI Source Popup

DI Source Popup - The DI SRC button enables and disables the asynchronous sample rate converter (SRC) in the Mobile I/O digital audio receiver. When the SRC is engaged (button illuminated yellow), the digital audio receiver will automatically synchronize the input signal to the Mobile I/O system clock over a wide range of sample rate ratios.

DI SRC ButonThis allows you to, for example, digitally transfer a sample from a CD player into a 96k session without any clocking problems. If you want to make bit-transparent transfers, you will need to disengage the SRC and ensure that the Mobile I/O and the external device are both using the same digital audio clock via one of the Mobile I/O synchronization mechanisms.

DI SRC ButonThis allows you to, for example, digitally transfer a sample from a CD player into a 96k session without any clocking problems. If you want to make bit-transparent transfers, you will need to disengage the SRC and ensure that the Mobile I/O and the external device are both using the same digital audio clock via one of the Mobile I/O synchronization mechanisms. - The Lock indicators show which elements of the Mobile I/O clocking system are properly locked. The clocking system must be locked for the unit to behave as expected. If the system is not locked, audio will play at the wrong rate and will be distorted or noisy. Under normal circumstances, the system should always be locked, but if you have selected an external clock source and the clock signal is not present, corrupted or out-of-range, the system may unlock. There are indicators for the system and the digital input.

Lock Indicators

Lock Indicators

ANALOG OUTPUT CONTROL

The bottom half of the panel is dedicated to the hardware outputs of the Mobile I/O. Much like the analog inputs, each of the eight analog outputs has a set of controls associated with it. The controls are similar to the analog input controls. If these controls are "grayed out", it is because they are referenced by the Monitor Controller, which removes direct control from this panel. If you want to control the analog output from this panel, you must remove the Monitor Control output path that references it. Each output channel has:

-

Parameter Popup control — The Parameter Popup control allows you to save, recall, and manage the parameters associated with an analog output in one place. The control is documented in detail here. All presets are automatically shared between all of the output channels.

Level Standard popup menu — This control allows you to select the output level for the channel. The available choices are:

- Line +4 This format supports output levels up to +26 dBu. The standard setting with the trim knob set to 0dB yields a +24dBu output when the digital signal driving the DAC is 0dBFS. This corresponds to +4 dBu nominal with 20dB of digital headroom. You can use the trim knob to adjust the analog output level to be consistent with the needs of other audio gear. The output impedance is approximately 50 Ohms. This format is appropriate for interfacing with professional audio equipment.

- Line -10 This format supports a nominal output level of -10dBV with 20 dB of digital headroom. You can use the trim knob to adjust the analog output level to be consistent with the needs of other audio gear. The output impedance is approximately 50 Ohms. This format is appropriate for interfacing with prosumer and consumer audio equipment.

Gain Trim knob — The Gain Trim knob allows you to adjust the analog gain of the output stage (post DAC) over a 40dB range determined by the output standard that you have selected. The gain is indicated in dB relative to the nominal level of the output standard you have selected. The gain changes are smoother near the bottom of the scale, with the steps increasing in size as you reach the +40dB gain limit. Unless the signal is quite low, you will put the output stage into analog clipping well before you hit the 40dB gain limit.

- Channel Label — This simply labels which channel is associated with the output.

- Channel Level Meter — This is a peak reading, high-resolution fast PPM meter. It shows the pre converter level of the output signal of the associated channel. The peak hold bar indicates the highest level seen on the channel since the last reset. You can reset the hold by clicking on the meter. These meters are simply high resolution versions of the meters shown on the front panel of the box – all the meter data is generated by the Mobile I/O hardware.

ANALOG OUTPUT CHANNEL LINK

In addition to the channel specific controls, each channel pair shares a Link button. When the Link button is engaged, changes made to one channel of the pair will automatically be applied to the other channel of the pair. This is very useful if you are driving a stereo monitor section or stereo device. By engaging the Link button, you will ensure that both channels have precisely the same amount of analog gain applied post DAC. When you enable the Link button, the control values for the odd channel in the pair will be copied to the even channel of the pair.

DIGITAL OUTPUT METERS

To the right of the Analog Output controls is the Digital Meters section. This group of meters provides level metering for all of the digital outputs on the Mobile I/O. These meters have the same response characteristics as the analog output meters, and show you the audio activity on ADAT output channels 1-8 and digital output channels 1-2, going from left to right. The ULN-8 shows AES output channels 1-8. Please note that when the box is clocking at 2x rates (88.2-96k), the ADAT output is not useable. Both channels of the stereo digital output remain active at all sample rates on the 2882 and ULN-2.

The label above the bank of 8 channel meters is a popup control that allows you to select between ADAT optical format and TOSLINK Optical SPDIF for the optical output connector. Click on the control to popup a menu to select between the different modes of operation. The mode is independently selectable for both the input and output.

If you have selected TOSLINK for either the input or output section, you will only see meters for channels 1+2 of the optical digital section. These correspond to the levels that are being transmitted or recieved in the optical SPDIF signal.

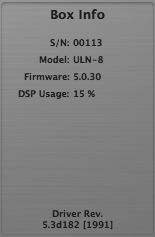

BOX INFO

The Box Info section of the panel, in the lower right-hand corner of the window, shows you information about the currently connected and selected Mobile I/O unit. This section displays the Serial Number, Model Information and Firmware revision of the connected box as well as the Driver revision. All of this information can be useful in trying to track down any connection problems that may arise.

If there is no information displayed in the Box Info section, the software is not communicating properly with the Mobile I/O hardware, or there is no Mobile I/O present on the FireWire bus.

If the FireWire light on the front panel of the Mobile I/O is illuminated but the box information does not appear in the console window, it is very likely that the software has not been installed properly. If this is the case, please refer to the installation instructions for details on how to properly install the software.

If, on the other hand, the FireWire light on the front panel of the Mobile I/O is not illuminated, the box is not communicating properly with the computer. Please check the cabling of your Mobile I/O and other devices on the FireWire bus and make sure that everything is connected correctly. If that does not properly establish the connection, try rebooting your computer. As a last resort, try connecting only the Mobile I/O to the computer to ensure that communication can be established.

The Box Info section also shows the DSP usage of the connected box. This is a rough indication of how much of your interface's 2d DSP is being used. This includes mixers and plug-ins. This does not reflect the memory being used. It is possible to use less than 100% DSP but still overload the system if you instantiate too many delays or reverbs.

PARAMETER POPUP CONTROLS

The Parameter Popup control is MIO Console’s unified mechanism for handling presets for the various sections of the Mobile I/O. Each element of the console that supports the Parameter Library mechanism has a parameter popup control associated with it. These elements include:

- Input Channels (superseded by the Mixer Window)

- Output Channels

Each instance of the Parameter Popup control provides the same commands and options for every section of the console.

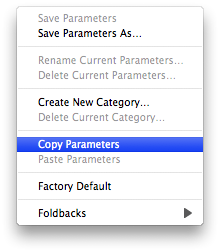

POPUP COMMANDS

The parameter popup provides a hierarchical, categorized library of configuration presets for the associated section of the console. The menu is divided into three portions. The first portion consists of all of the items above the “Factory Default” item. The second portion is the “Factory Default” item and the third portion is the hierarchical items below the “Factory Default” item (see Parameter Popup Menu ).

The commands in the first portion of the menu allow you to save and manage the presets in the library. All of the presets are shared between like elements in the console. The preset commands are:

- Save Parameters — use this command to save the current state of the associated console settings to the currently selected preset (will appear as “Save Parameters As…” if there is no currently selected preset)

- Save Parameters As… — use this command to name and select a category to save the current state of the associated console settings as a preset into the library

- Rename Current Parameters… — use this command to rename the currently selected preset

- Delete Current Parameters — use this command to remove the currently selected preset from the library

- Create New Category — use this command to add a new category to the library

- Delete Category — use this command to delete the currently selected category and all of its associated presets

- Copy Parameters — use this command to copy the current state of the associated console settings to the clipboard; you can use this to copy your settings from one block to another

- Paste Parameters — If the clipboard contains compatible settings, this command will be available and will set the current state of the associated console settings to the settings on the clipboard. Use this with the “Copy Parameters” command to duplicate settings from one channel to another or from one mix to another

The “Factory Default” command will set the current state of the associated console settings to the default settings.

POPUP PRESETS

In the third part of the menu, each of the categories will be listed as a hierarchical menu title. Each of the presets for each category will be listed in the submenu under the category menu. The currently selected category and preset are drawn in bold, so you will know what is currently active.

Selecting a preset from the menu will make that preset active and will set the current state of the associated console settings to the values contained within the preset. The name of the currently selected preset will be drawn in the popup area in the console window to indicate which preset is active.

If you change the settings in the console, the name of the preset will be drawn in italics indicating that the current settings differ from the selected preset.

For the Input and Output channels, you can hold down the <option> key while selecting a preset to automatically apply the preset to all of the other input or output channels.

To access the parameter popup for the mixers, either click and hold the associated mixer tab or <control> click the associated mixer tab.

We have provided an initial set of presets for the various parameter libraries. The presets for the output channels are relatively complete and give you an idea of the power and flexibility of this approach to parameter management.

THE MIXER WINDOW

Perhaps the most fundamental thing for you to understand is that the v.5 mixer model is based upon user-configuration. The advantage to this is that you can build the exact mixer you need for any specific task or set of circumstances. But it does mean that the v.5 mixer window is blank until you configure it.

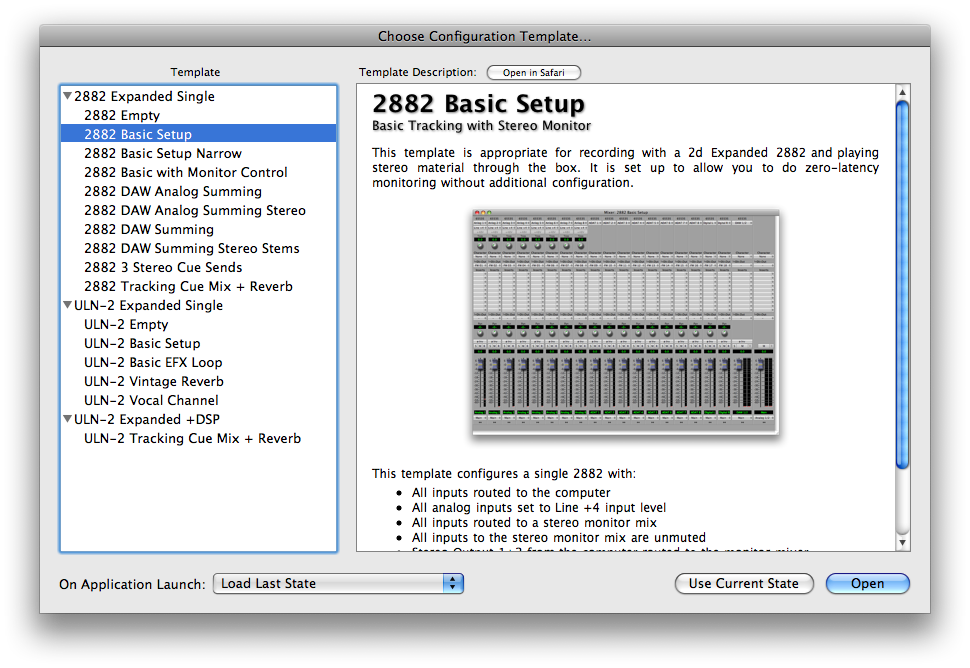

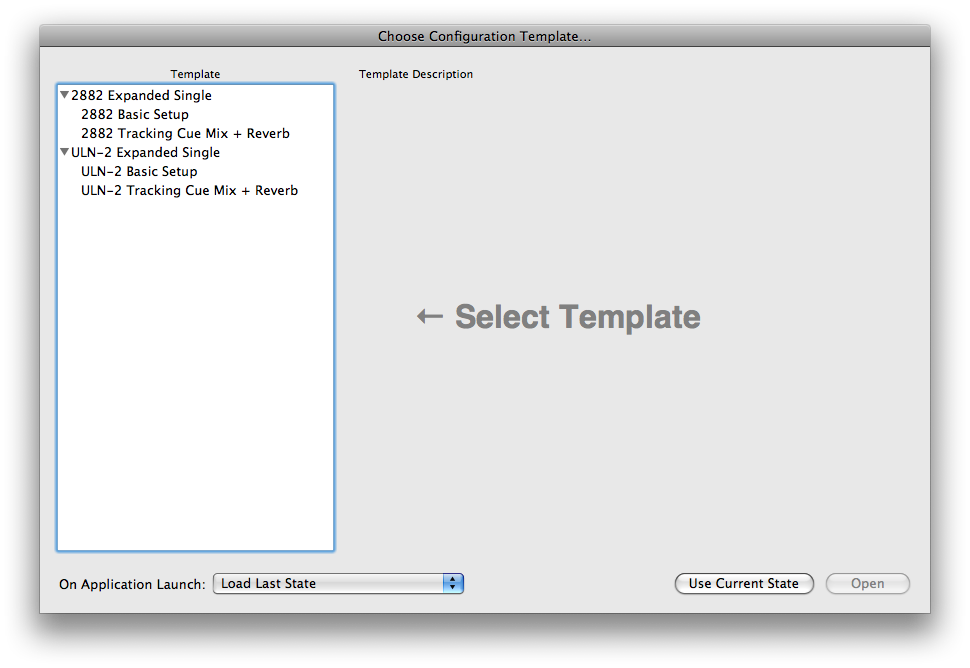

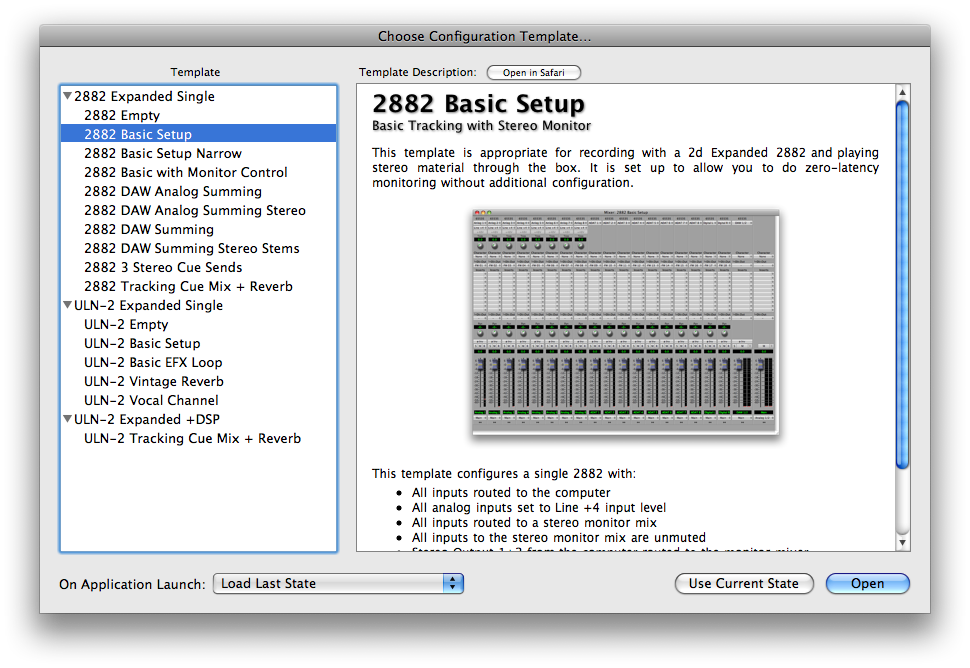

In order to avoid the “blank page” syndrome you can use one of the templates we've included with the software. The template selection dialog is displayed on first launch, and it can be accessed at any time from the File menu.

Template Selection Dialog

Alternatively, you can use the following steps to configure a mixer from scratch.

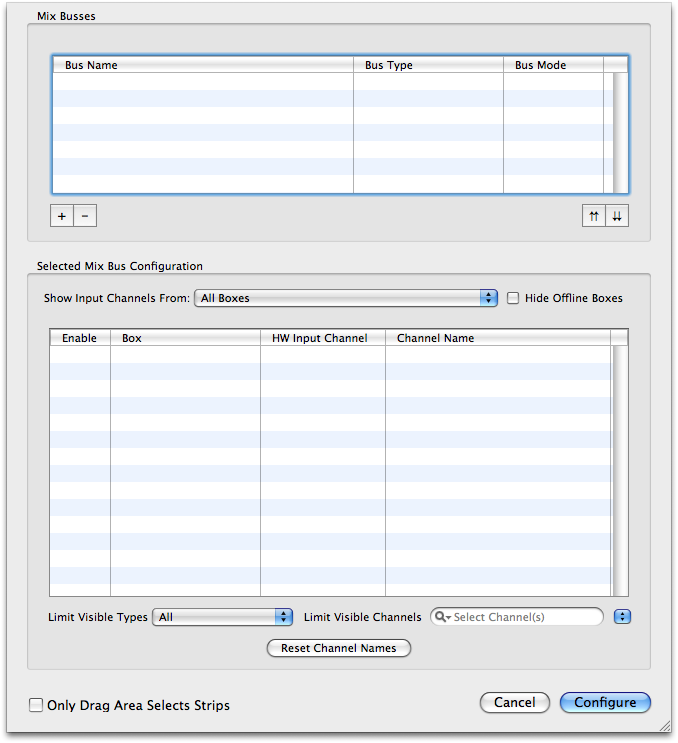

The easiest way to create a new mixer configuration is to use the Mixer » Configure Mixer… menu command. Selecting this command presents the Configure Mixer sheet, which allows you to do bulk configuration of the mixer.

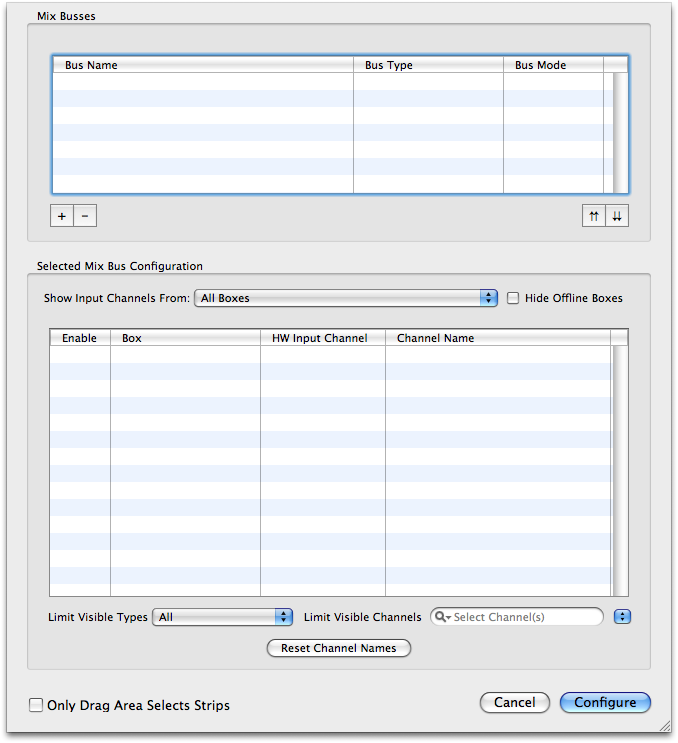

Configure Mixer Sheet

The sheet is split into two major sections:

- Mix Busses

- Selected Mix Bus Configuration

You create and configure the mix busses using the top section, then you configure the channels you assign to the busses in the bottom area. When you select a mix bus from the table in the Mix Busses section, the Selected Mix Bus Configuration area automatically updates to reflect the current configuration of the selected mix bus. All of the available input channels are listed in the Selected Mix Bus Configuration, and you can assign any of the channels to the selected mix bus by checking the channel’s Enable check-box.

To Create a Mix Bus:

- Click the “+” button — this creates a new stereo bus with a default name.

- Double-click the new bus in the list; you can now edit the bus name.

- You can adjust the bus type with the popup in the Bus Type column.

To Delete a Mix Bus:

- Select the bus you want to delete

- Click the “-” button — this deletes the bus and de-assigns the channels assigned to the bus (but it won’t delete the channel strips from the Mixer window).

To Add an input channel to a Mix Bus:

- Select the bus to which you want to add a channel.

- Check the box in the “Enable” column for the channel you want to add to the bus.

To Remove an input channel from a Mix Bus:

- Select the bus from which you want to remove the channel.

- Uncheck the box in the “Enable” column for the channel you want to remove from the bus.

When you have finished configuring your mixer, click the Configure button in the bottom right. The mixer you have configured will now appear in the Mixer window.

The v.5 Mixer removes the direct-route connection between the physical inputs and FireWire that has existed in the Mobile I/O since it was originally shipped. Instead, the v.5 Mixer extends and enhances the concept of FireWire returns. In fact, all audio is now sent to the computer via FireWire returns. In other words, if you want to send audio from your Mobile I/O's inputs to your computer, you will need to assign those inputs to FireWire returns manually via the Direct Outs in the mixer input strips. Hint: selecting “Auto” in an input strip's direct output pop-up menu will automatically assign the direct out to the next available FireWire output.

The Mixer you have created will automatically contain Input channel strips for all of your configured channels, and a Master channel strip for the Mix Bus. Now you'll just need to route your Master strip to the desired physical outputs using the Bus Output pop-up menu at the bottom of the Master strip, and you can hear all the inputs assigned to that mix bus through your MIO outputs. See below for more details about Master Strips.

Ultra-Quick Start Summary

To quickly configure a mixer that will send your selected inputs to your studio monitors and to your computer:

- Select the Mixer » Configure Mixer… menu command.

- Create a Mix Bus as described in “To Create a Mix Bus” above.

- Add input channels as described in “To Add an input channel to a Mix Bus” above. Be sure to add some physical inputs and some DAW inputs so you can route both physical and computer inputs through the mixer.

- When you have finished Enabling the input channels you wish in your mixer, click the Configure button in the Configure Mixer sheet to create your mixer.

- In the Input channel strips for each of your physical inputs, click on the Direct Output pop-up menu (either pre- or post-send, up to you), select "Auto." This assigns each Input strip to a FireWire output.

- In the Master Strip, click the Bus Output pop-up menu and select the physical outputs to which your studio monitors are connected.

That's it! You've just created your first v.5 mixer. You can now route the audio signal from your Mobile I/O's physical inputs to your computer, from your computer to your Mobile I/O, and connected the mixer to your studio monitors.

Introduction

The v.5 Mixer Architecture represents a quantum leap forward in both the power and usability of the Mobile I/O's mixing/routing/signal processing engine. This new architecture builds upon signal processing elements that have been in development at Metric Halo since the initial introduction of the Mobile I/O in 2001.

With the introduction of the v.5 architecture, we have taken the basic interaction model of MIOConsole and we have re-engineered it based on the feedback we've received from our users and beta-testers over the years.

The v.4 took the approach of defining precisely what the hardware was capable of; you had to adjust your workflow to fit its capabilities. The v.5 mixer takes the approach of assuming nothing about the configuration of the hardware, allowing you to define your configuration up to the limits of the hardware. This has a number of significant benefits to the user:

- You only utilize the resources you need. This conserves resources, allowing you to direct more DSP towards what you are focussed on without having resources utilized by functions or features that are irrelevant to your task-at-hand.

- The UI directly reflects the elements of the hardware that are of interest to you, and does not present elements that are superfluous to the work that you are trying to accomplish.

- The configuration-based UI allows us to directly integrate features such as routing into the UI of channels that you have added to your configuration. This enables us to provide you with a direct-routing model that is easier to understand than the v.4 model, while still as powerful as the full-graph routing model.

But again, keep in mind that the consequence of the v.5 model being based upon user-configuration is that the Mobile I/O is a blank slate until it has been configured by you.

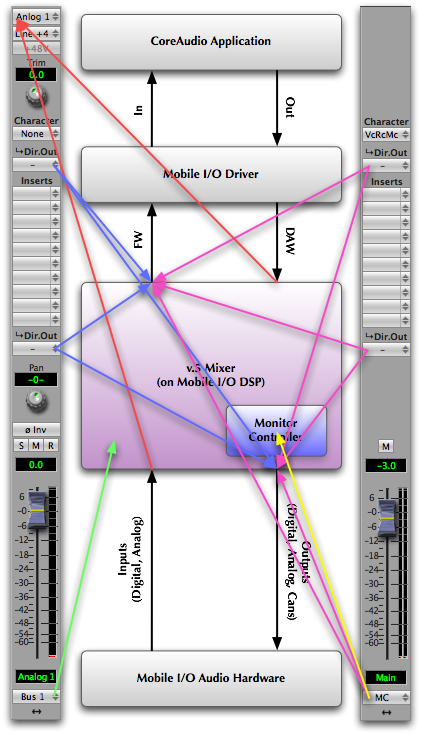

Routing

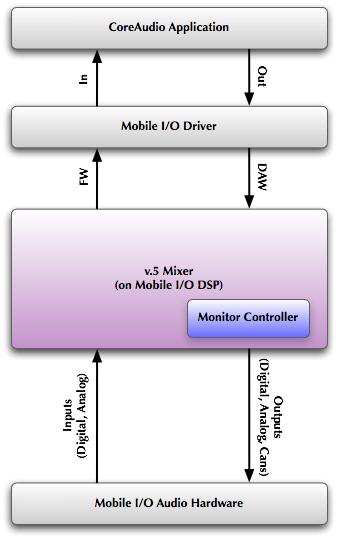

The v.5 Mixer removes the direct-route connection between the physical inputs and FireWire that has existed in the Mobile I/O since it was originally shipped. Instead, the v.5 Mixer extends and enhances the concept of FireWire returns. In fact, all audio is now sent to the computer via FireWire returns. The following illustrates the overall routing structure of the Mobile I/O with the new v.5 mixer:

v. 5 2d Routing Model

As you can see, instead of the hardwired direct-routing of inputs found in the previous Mobile I/O console, now all of the audio streams that are sent to the computer have been converted to FireWire returns. The mixer now provides the facilities to easily route any of the audio in the system to the computer — even between applications!

Routing is critical!

It is very important to understand that the v.5 mixer does not provide default routings!

You must choose where you want your audio to go. If you don't route a mix bus to a physical output, you will not hear any audio. If you don't route an input to FireWire it will not be available to any applications in your computer.

Routing in v.5 is really easy — so just remember — if you are not hearing or seeing your audio where you expect to, check your routings!

A Quick Tour of the v. 5 Mixer

The v.5 mixer provides many new features as well as greatly simplifying the use of older features. The mixer provides the following functions:

- An arbitrary number of mix busses (limited only by DSP

resources).

- Each bus supports a configurable width (mono to 7.1 surround)

- Each bus provides full metering

- Any bus may be used as an input source for any other bus

- An arbitrary number of channel strips.

- Each channel strip may be fed by any available source in the system (including physical I/O, FireWire, DAW returns, or busses in the system.

- Channel strips for physical I/O provide direct access to any available I/O controls (like phantom power or input trim).

- Each channel strip provides a phase invert button.

- Each channel strip offers our unique Character processing control.

- Each channel strip provides a pre-insert Direct Out routing point to route the channel strip to any Physical Output or FireWire Return. This may be used for recording dry signals and/or routing the MIO as a stand-alone A/D converter.

- Each channel strip provides ten (10) Plug-in insert slots.

- Each channel strip provides a post-insert Direct Out routing point to route the channel strip to any Physical Output or FireWire Return. This may be used for recording wet signals and/or routing signals through the MIO to use it as a signal processor.

- Each channel strip provides a bus-type sensitive panner. For mono strips, there is no panner; stereo and LCR strips contain a knob panner and for LCRS and beyond include a surround panner.

- Each channel strip provides a record-enable button that is linked to the record panel.

- Each channel strip provides a mute button, solo button, and level fader.

- Each channel strip provides a meter that reflects the input level to the mixer.

- Each channel strip provides a bus-assign routing control to select which mix bus (or busses) will be fed by the channel strip.

- Each master mix bus also has an associated master strip with:

- Summing bus Character processing control.

- Pre-insert Direct Out routing point to route the master strip to any Physical Output or FireWire Return.

- Ten (10) Plug In insert slots.

- A fader to control the mix level — this master fader applies across all channels in the bus. Please note: This fader gain is applied before the direct outs and inserts in the strip.

- A meter that reflects the output level of the mixer. Please note: The bus meters reflect the post-fader, pre-insert level.

- Each master strip provides a record-enable button that is linked to the record panel.

- A mute to silence the entire bus.

- Each channel strip provides an output assign routing control to allow you to route the mix to any Physical Output or FireWire Return. This routing control allows you to create mults and assign the mix as a source for the Monitor Controller.

- Each Plug-in insert point can host plug-ins of the following type:

- Basic +DSP plug-ins (like MIOStrip, MIOEq, MIOLimit, etc.).

- Sends, used to send the signal from that point in the process chain to another bus

- Graph plug-ins, which implement a routable sub-graph. This allows the creation of complex +DSP patches that can be simply inserted into the overall signal path.

- Plugin Macros, which provide pre-configured signal processing engines. Some of these macros are monolithic — you cannot see or edit their internal structure; others are simply pre-configured graph macros that can be used as a starting point to create your own graphs.

-

The routing features of the mixer’s input channel and master strips provide greater routing flexibility than v.4’s patchbay + FireWire return implementation while also being easier and faster to configure. Since routing is done directly from the appropriate point in the signal flow, it is also much easier to understand.

-

The plug-in insertion, routing and management features of the mixer’s input channel and master strips provide a much simpler and faster way to interact with plug-ins than v.4's DSP graph — an approach that is better suited to the needs of a production workflow. This coupled with the increased DSP power of the 2d Card allows for deep and sophisticated mixes to be created on the hardware with significant processing and no latency.

Thanks to the new routing functionality in the mixer, we have been able to completely remove the patchbay from the system. With the new routing and plugin functionality in the mixer, coupled with the availability of the Graph plug-ins, we have also been able to completely remove the overall +DSP graph interface from the system. These changes make utilizing the power of the Mobile I/O and +DSP far more elegant and intuitive.

The Mixer, Routing and +DSP panes in the MIO Console window are no longer required when all the units you are using have 2d Cards installed. If your entire system is 2d Card enhanced, you can disable these panes in MIO Console preferences. If you continue to use units that do not have 2d Cards installed, you will still use those panes in the MIO Console window to control those elements of your legacy units.

Technology

The v.5 mixer is based upon the +DSP graph technology originally designed for +DSP. With the 2d Card, we have created the concept of an Übergraph. The Übergraph is an internal +DSP graph that represents the entirety of the Mobile I/O, including the 2d DSP, all the physical I/O and the FireWire I/O. Since the +DSP graph provides infinite routing and multing capabilities with integrated latency compensation, the addition of full access to all I/O resources means that everything can go everywhere in the new system.

What’s up with the Übergraph?

While the v.5 mixer is based upon the Übergraph, it does not require (and, in fact, does not allow you) to interact directly with the Übergraph. Rather, the v.5 mixer manages all of the plug-ins and connections within the Übergraph for you. So, even though you may be creating an incredibly complex network of plug-ins with many mults and bus to bus routes, the user interaction required for you to control the system is simple and direct. This explanation of the Übergraph is included to give you a deep understanding of the v.5 architecture, nothing more.

The v.5 mixer works as complex routing manager, adding plug-ins (including mixer plug-ins) to the Übergraph based upon your configuration commands. Because the +DSP engine automatically configures the runtime environment to compensate for routing latency in the configured DSP graph, you can rely on the fact that bus to bus routes all arrive with no routing latency. This allows you to configure sub-mixes and stems, including sub-bus processing, without having to worry about phase-cancellation problems or other latency related issues.

The v.5 mixer builds a model of your desired mix bus structure and also tracks all of the routes that you create between busses, bus outputs and direct outs. The mixer then ensures that everything stays routed properly as you add and remove plug-ins, channels and busses. This technology makes the manipulation of your mixer and routing simple — rather than think about how to route the elements of the mixer, you simply insert things where you want them and the mixer takes care of all the routing for you. Since the model is based upon the +DSP graph, you have much more flexibility in your routing options with regards to arbitrary sends, I/O, direct outs, and mults than you have in most digital mixers.

Configuration

As described above, the v.5 mixer starts with a clean slate — nothing connected:

Blank Mixer Window

In order to use the Mobile I/O with v.5, you must have a mixer configured. This means that you need to load one of the supplied mixer templates (using the "Open Template..." command), a saved MIO Console Settings file (if you have one), or you can create a new mixer configuration.

Using Templates for Configuration

The easiest way to create a new mixer configuration is to start with a template using the File » Open Template… menu command. When you select this command, you are presented with the "Choose Configuration Template..." window:

Template Window

Selected Template

Once you decide to use the selected template, click the Open button. If you decide that you don’t want to use one of the templates, you can click the “Use Current State” button to use the state that is currently loaded in the console. If you are using the Template dialog at application launch, this will load the state that the console was in the last time you quit MIO Console. If this is your very first launch ever of the MIO Console, you will then need to manually configure your mixer.

Manual Configuration

The next way to create a new mixer configuration is to use the Mixer » Configure Mixer… menu command. When you select this command, you will see the Configure Mixer sheet:

Configure Mixer Sheet

The Configure Mixer Sheet allows you to do bulk configuration of the mixer. The sheet is split into two major sections:

- Mix Busses

- Selected Mix Bus Configuration

Each mix bus has a number of attributes that you can control:

- Bus Name

- Bus Type

- Bus Mode

The Bus Name is the name you assign to the bus. It is used throughout the Mixer UI to identify the bus. You can name the bus anything you like.

The Bus Type determines the number of channels of the bus (mono, stereo, etc.). The type of bus determines the type of panner used to connect the input-strips to the bus. We have implemented the following types so far:

- Mono

- Stereo

- LCR - Left, Center, Right

- Quad - Four-corner surround

- LCRS - LCR with one back-channel

- 5.0 - LCR with left surround and right surround

- 5.1 - 5.0 with LFE

- 7.1 - 5.1 with Left-Center and Right-Center

The Bus Mode allows you to determine if the bus has a master fader or not. If the mode is Master Mix the mixer will create a master fader for the bus. If the mode is Aux Bus the mixer will not create a master fader, but you can assign the bus to another bus to create a return fader.

Mixer Configuration Tasks

The following task lists are succinct guides to performing the specific configuration tasks you will need to engage in while configuring a mixer using the Configure Mixer Sheet.

To Create a Mix Bus:

- Click the “+” button — this creates a new stereo bus with a default name.

- Double-click the new bus in the list; you can now edit the bus name.

- You can adjust the bus type from the pop-up menuin the Bus Type column.

To Delete a Mix Bus:

- Select the bus you want to delete

- Click the “-” button — this deletes the bus and de-assigns the channels that were assigned to the bus (but it won’t delete the input channel strips in the mixer).

To Add a channel to a Mix Bus:

- Select the bus to which you want to add the channel.

- Check the box in the “Enable” column for the input channel you want to add to the bus. Your choice of input channels consists of any of the physical analog and digital inputs from your Mobile I/O, as well as any available inputs from your computer (called "DAW" inputs). The channels you select here are the channels that will be available in your mixer as Input strip destinations.

To Rename an Input Channel in a Mix Bus:

- In the "Channel Name" column, double-click the name you wish to rename.

- Type the new name of the input channel.

To Remove a channel from a Mix Bus:

- Select the bus from which you want to remove the channel.

- Uncheck the box in the “Enable” column for the channel you want to remove from the bus.

To Add/Remove all visible channels to/from a Mix Bus:

- Select the bus you want to configure.

- <option>-click one of the checkboxes in the “Enable” column. All visible channels will be added or removed from the Mix Bus.

To limit the channels visible in the Selected Mix Bus Configuration area:

- Select the bus you want to manipulate.

- Type the text that you want to use to limit the channels visible in the

table.

- You can click the pop-up menu next to the search field to quickly enter certain standard search text items (like “Analog” or “DAW”)

- You can click the pop-up menu inside the search field to choose which column is searched for the text

- To remove the limitation, delete the text in the search field or click the X in the circle in the search field.

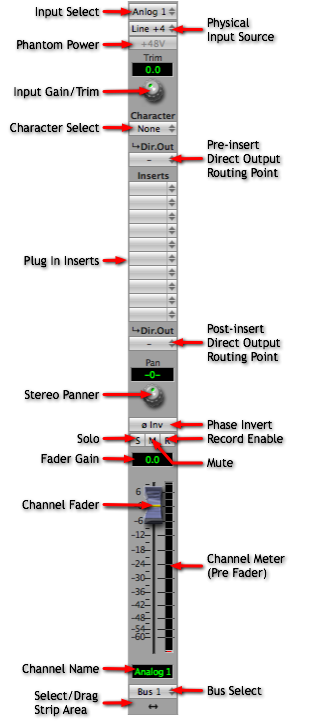

Input Strip Details

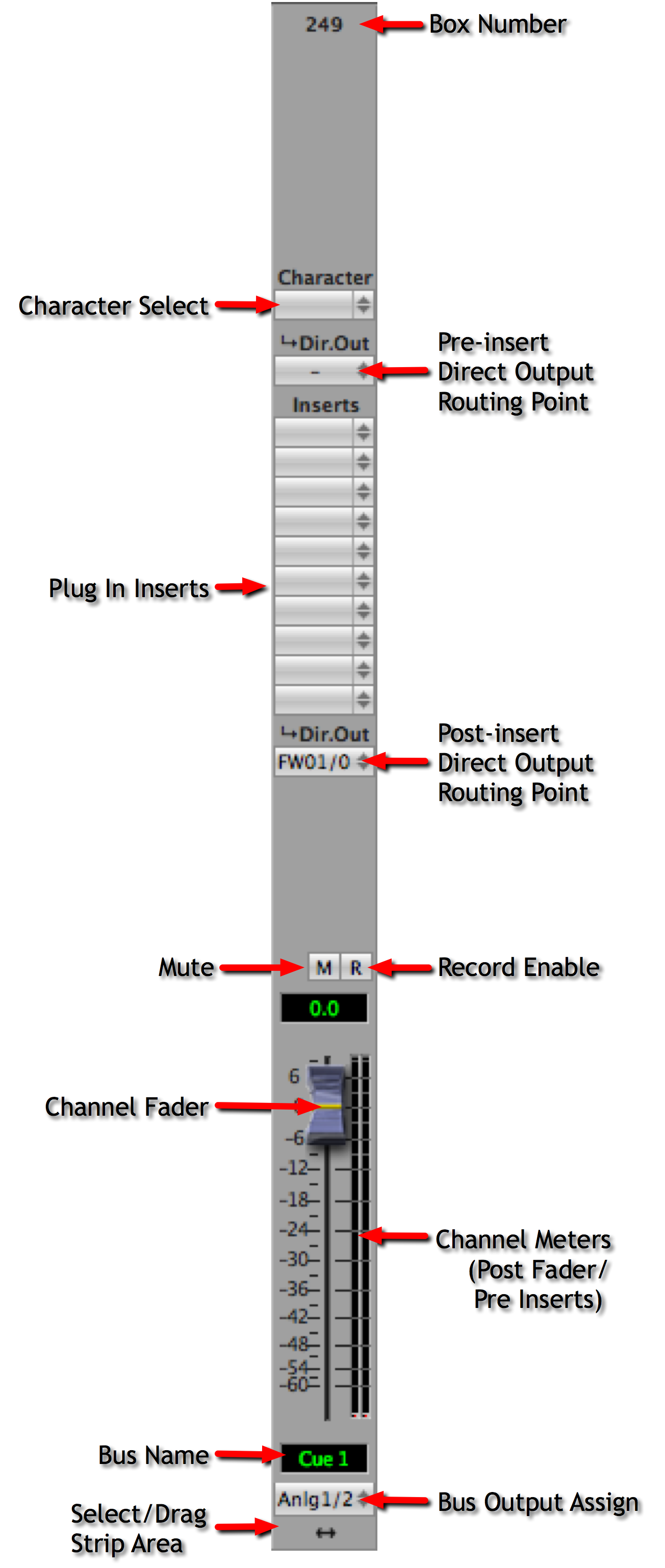

Every Input strip in the v.5 mixer has a similar set of controls. The following figure shows each element with a label; a detailed description follows below:

- Input Select: This pop-up menu lets you choose the audio source for the input strip. You can select either a physical input or the output of a bus. For a physical input, there may be further physical routing that can be selected using the Physical Input Source popup.

- Physical Input Source: This pop-up menu will be present if the source you choose in the Input Select pop-up menu has further physical routing or level control selections available. For example, the Analog inputs on the 2882 allow for the selection of Line +4, Line -10, Mic, Mic/Pad and Instrument inputs. This popup allows you to make those selections. (Note: the Physical Input Source controls are identical to those on the I/O Control tab of the MIO Console. Changes made tothe Physical Input Source items in the Mixer window and vis versa). If the input does not have these sort of selections (such as a digital input), then this control will not be present.

- Phantom Power: This button will be present if the physical input supports phantom power. Click this button to enable the digitally controlled phantom power. The button is red when phantom power is enabled.

- Input Gain/Trim: This knob and numeric display will be present if the physical input supports digitally controllable analog input gain. The knob automatically adjusts the gain between the available minimum gain and maximum gain for your hardware. You can also type a gain amount directly in the Input Gain/Trim numeric display. If you type in an amount that is below the minimum allowable gain, the gain will be set to the minimum allowable. If you type in an amount that is above the maximum allowable gain, the gain will be set to the maximum allowable. The display readout is in dB.

- Character Select: All input strips support this control which allows you to select which character model will be applied to the input signal. The various character models offer unique, high quality harmonic and tonal coloration to your signal. Choose "None" to disable character modeling.

- Direct Output Routing Point (pre-Inserts): As signal runs through the input strip there are a number of points from which you can route the signal to an output. This Direct Output pop-up menu controls the first available route point. This route point is "pre-insert," meaning it occurs before any plugin processing is applied to the signal. You can choose any Physical Output or FireWire Return on the same box as the destination for this Direct Out. If you choose the "Auto" item in the menu, the mixer will automatically route to the next available output. This routing point is the appropriate one to use for "Dry" recording — meaning that you are only using the Mobile I/O as a preamp and converter, and not for any of its mixing abilities or DSP plug-ins.

-

Plug-in Inserts: Like the "insert slots" in modern DAWs, these pop-up menus function as inserts into the signal path, allowing you to insert any of the available plug-ins directly into the signal path. The processes are applied sequentially from top to bottom. If you have a multi-channel input channel strip, you can still insert mono plug-ins on the strip; the mixer will automatically insert enough plug-ins to process every channel in the strip and will also automatically link all the mono instances together. This allows you to use the full range of +DSP plug-ins on multi-channel input strips.

In addition to standard plug-ins, you can also insert plugin graphs directly into the strip. When you insert a plugin graph, the signal in the strip is connected from the output of the preceding slot to the input of the inserted graph and from the output of the graph to the input of the next slot. Within the inserted graph you can do all the cool +DSP tricks that you have always been able to do, including feedback loops, mults, and so on. This allows you to build complex processing graphs and easily insert them into your production workflow.

- Direct Output Routing Point (post inserts): This pop-up menu controls the second and last available route point. It occurs "post-insert" meaing it occurs after any plugin processing from the inserts has been applied to the signal. You can choose any Physical Output or FireWire Return on the same box as the destination for this Direct Out. If you choose the "Auto" item in the menu, the mixer will automatically route to the next available output. This routing point is the appropriate one to use for "Wet" recording — meaning that in addition to using the Mobile I/O as a preamp and converter, you are also utilizing it to apply DSP processes into your record channel.

-

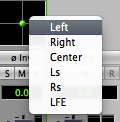

Panner: Stereo and multi-channel input strips include a panner section. This is a context

sensitive control; in other words, the type of panner that appears depends on the number of channels on the input channel strip. If the mix bus is a mono

bus, there will be no panner. If the mix bus is Stereo bus or a three-channel

LCR bus the panner will be a knob control with pan display. If the mix bus is a 4-channel or

higher bus, the panner will be a surround panner. Use the panner to position the

channel in the mixer's sound field. The different panner controls look like:

v.5 Mixer Direct Pan Assignment

- Phase Invert: Clicking this button will invert the phase of the input signal at the mixer input. The button turns yellow when enabled.

-

Solo: When any solo button is engaged on any channel in a mix bus,

the mix bus will only pass signal for channels that have the solo button

engaged. This solo functions as a solo-in-place, meaning all pan, level, and DSP processing settings on the channel strips are maintained. Having solo engaged does not

effect the signal at any of the direct outs.

The solo button turns orange when engaged.

- <command> click on any solo button will clear all solos in the bus except for the solo you click on.

- <option> click on any solo button will set all solos in the bus to the new value — you can use this to clear all solos on the bus.

-

Mute: When this button is engaged signal in the associated channel

is muted at the mixer. This does not effect the signal at the direct outs.

The mute button turns blue when engaged.

- <option> click on any mute button will set all mutes in the bus to the new value.

-

Record Enable : This button enables recording of the associated channel(s) in the record panel. The Record Enable button turns red when engaged.

- <option> click will set all record enable buttons in the bus to the new value.

- Fader Gain display: Shows the channel gain level in dB. Click in the readout display to edit the level numerically.

- Channel Fader: This fader allows you to adjust the channel gain level.

- Channel Meter: This meter shows the pre-fader, post insert signal level.

- Channel Name: Shows the name assigned to the channel in the Mixer Config sheet. You can rename each channel using the Mixer Config dialog window as explained above in "Mixer Configuration Tasks."

- Bus Select: Use this pop-up menu to select the bus that the input channel strip is assigned to.

-

Select/Drag Strip: This area lets you select an input channel strip and move the strip either right or left within

the mixer.

- Clicking in this area will select the strip if it is not already selected.

- <command> click will toggle the selection.

- <shift> click will add strips to the current selection. All strips between the shift-clicked strip and the currently selected strip will become selected.

- Click and drag to move the selected strips left or right in the mixer.

You can click outside any strip to deselect all strips.

Selection-based Linking

When you have multiple strips selected, the changes you make to a selected strip will be applied to all the selected strips. For example, if you have multiple input channel strips selected and you choose a setting for "Character" on one of the selected strips, that setting for Character is applied to all selected strips.

This feature allows you to quickly apply bulk changes to the state of the mixer.

The parameters that are linked by selection are:- Physical Input source

- Character

- Pre-insert Direct Out, if you select Auto or n/c

- Any Plug In Insert — the same plugin will be inserted on each selected strip

- Post-insert Direct Out, if you select Auto or n/c

- Phase Invert

- Solo

- Mute

- Record Enable

- Bus Assignment

- Dragging — all selected strips will be consolidated and dragged as a block

- Input Gain/Trim

- Pan position

- Channel Fader Gain

Plug Ins

The v.5 Mixer provides an insert model for using +DSP plug-ins. The 2d Hardware includes a basic set of plug-ins that provide "nuts & bolts" production processing:

- MIOStrip — a complete channel strip plugin which includes:

- Gate w/ sidechain filter

- Compressor w/ sidechain filter

- 6-band EQ

- MIODelay — a short time track alignment delay

- M/S Decoder

- Dither

- Simple Reverb

- Metric Halo’s exclusive Character signal processing per channel

- Multichannel mixer with surround support

- Bus send plugin for routing signals within channel strips to busses

When the +DSP license is added to 2d, the options grow dramatically. All +DSP plug-ins can be inserted directly into the insert slots in the channel strips, or you can insert a +DSP graph into any of the insert slots, and then insert and connect a graph populated with +DSP plug-ins within the inserted graph.

The plug-ins that may be inserted in any given slot depend on the number of channels of a given input channel strip. All mono plug-ins may always be inserted in any slot; if you insert a mono plugin into a strip that has a multichannel input (for example a bus master strip or bus return strip, or a multichannel input strip), the mixer will automatically instantiate multiple copies of the plugin (for example — two plug-ins into a stereo strip and 5 plug-ins into a 5.0 strip), and link the parameters of the instances so that when you control the inserted plugin, it will control all instances.

If you are working with a multi-channel strip, only plug-ins that make sense for the number of channels of the strip will also be available; for example, with a stereo strip, you will see both the mono and stereo versions of the MIOComp and MIOLimit dynamics processors; you can select the version that works best for you. At the present time, there are few processors that have specifically been built for multi-channel strips with more than two channels. If you expect to use (or change to) a bus with multiple channels beyond stereo, you will probably want to use the mono version of the plugin as they can be automatically instantiated as you adjust the number of channels of the strip.

More info on using plug-ins via inserts can be found here.Plug In Graphs

When you insert a graph in the mixer, the graph is automatically generated with input and output ports to match the number of channels of the strip that it is inserted into. The default state of an inserted graph is for the inputs to be connected directly to the outputs.

When you open the graph UI for the insert, you can insert any set of plug-ins into the graph that is shown in the graph UI window. These plug-ins can be connected by virtual cables, their UIs opened, and parameters set. The graph I/O connections will automatically be routed to the appropriate points in the strip that hosts the graph. The graph will be saved and recalled with the rest of the mixer, and you can also choose to save the graph independently as kind of a "macro" that can be inserted again and again into the mixer.

The graph inserts also have access to the saved graph patch library — this lets you migrate patches that you have created in +DSP in v.4 or earlier to inserts in v.5. You can also save the configuration of your graph insert into the library as a preset, so as you work with the mixer, you can build up a set of "secret weapon" processors that can be instantly recalled and tweaked as needed.

To Migrate Graph Patches from v.4 or earlier Consoles:

Graph patches created in v.4 or earlier consoles may require a little clean up for use with v. 5.

• If the graph patch you want to load is already set up to take input from Analog 1 (for a mono patch), Analog 1-2 (for a stereo patch) or Analog 1-N (for a multi-channel patch), then you can just use it directly in v.5.

• If the graph patch you want to migrate is set up to take input from another source (say Analog 6, or Digital, or DAW, or ADAT), you need to open the graph in the Virtual DSP area of the +DSP pane and change the inputs to patch to Analog 1 (for a mono patch), Analog 1-2 (for a stereo patch) or Analog 1-N (for a multi-channel patch). The same applies for output assignments. Make sure to set the outputs to Process Bus 1-N. Save the patch with the new input and output assignments and it is ready to be used in a v. 5 graph plug in.

Also, please note that v. 4 and earlier medium and long delays will not currently load on the 2d DSP. However, MIO Console v.5 includes new 2d compatible delays that you should be able to use to replace the older medium and long delays.

Graphs may be instantiated into any insert point of any type of channel strip, whether it is an input strip, aux return strip or a master fader strip. This allows you to configure (or utilize pre-configured) processing in a variety of ways as appropriate for the project that you are working on. For example, you can insert a one in-one out graph into a mono input strip to implement anything from a guitar amp model to a parallel compressor or a feedback delay. You might insert a 2-in 2-out on an aux return strip and build a stereo reverb or echo time domain processor to process the send bus; you would insert sends on the various input strips to route the audio to your reverb graph.

More info on using graphs can be found here.Plugin Macros

With a +DSP license, the v.5 Mixer also supports the direct insertion of Plugin Macros, which are premade Graphs. Metric Halo includes a number of bonus macros with the +DSP license, including reverbs, guitar processing models, mastering tools, delays and other effects. Some of the macros are open — once you insert the macro, you will have full access to the graph, and you can edit it, modify it and interact with it as you please. Other macros are closed and represent a monolithic processor; you can insert them, and they do the job they were designed for, but they cannot be edited.

Sends

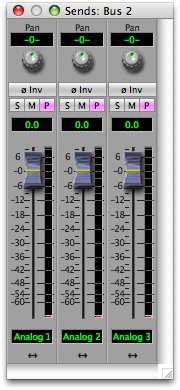

Any insert in the mixer may be used to send the audio from that point in the signal path to any bus defined in the mixer. When you insert a send to a bus on a strip, a new send strip is automatically added to the mixer; when you insert a send or click on a send tile in the mixer, MIOConsole will automatically open the Sends Mixer window:

Sends Mixer Window

The Sends Mixer window shows the all the send strips for the currently selected bus. Send strips are more limited than full input strips. Each Send Strip has a panner (if appropriate for the bus width and send width), phase invert, solo, mute and pre/post fader buttons, as well as a send level fader and level meter. All of the elements common with the full input strips function in the same way as the elements in the full strip.

The control element that is unique to the send strip is the Pre/Post Fader button (the lavender button with the "P" in the illustration above). When this button is illuminated, the send functions "Post Fader" relative to the mixer fader for the strip that the send is inserted on. This means that the level of the signal will be adjusted by the input channel strip's level fader. This is default state of the Pre/Post Fader button. Since the signal is actually routed from wherever the send is inserted, the "Post Fader" state does not control the routing of the send, but rather the level; the total send level will be the sum of the source fader level and the send level fader. When you have selected "Post Fader" mode for the send, the send will also respect the mute and solo state of the strip that the send is inserted on.

In "Pre-fader" mode, only the send level fader controls the level of the signal to the send destination. Also, the send does not take the mute or solo state of the strip into account when sending the signal to the send destination.

Master Strips

Master Strips are used to control the signal processing and output routing for mix busses. Rather like the Input Strips, they provide Character, Direct Outs, Inserts, and Mute controls. They also provide a very flexible strip output routing popup that allows you to route the output of the processed mix bus to any specific output path, mult it to many output paths, or to assign it to the Monitor Controller.

v.5 Mixer Routing Connections

- Character Select: All master strips support this control which allows you to select which character model will be applied to the input signal. The various character models offer unique, high quality harmonic and tonal coloration to your signal. Choose "None" to disable character modeling.

- Direct Output Routing Point (pre-Inserts): As signal runs through the master strip there are a number of points from which you can route the signal to an output. This Direct Output pop-up menu controls the first available route point. This route point is "pre-insert," meaning it occurs before any plugin processing is applied to the signal. You can choose any Physical Output or FireWire Return on the same box as the destination for this Direct Out. If you choose the "Auto" item in the menu, the mixer will automatically route to the next available output. This routing point is the appropriate one to use for "Dry" recording — meaning that you are only using the Mobile I/O as a preamp and converter, and not for any of its mixing abilities or DSP plug-ins.

-

Plug-in Inserts: Like the "insert slots" in modern DAWs, these pop-up menus function as inserts into the signal path, allowing you to insert any of the available plug-ins directly into the signal path. The processes are applied sequentially from top to bottom. If you have a multi-channel master strip, you can still insert mono plug-ins on the strip; the mixer will automatically insert enough plug-ins to process every channel in the strip and will also automatically link all the mono instances together. This allows you to use the full range of +DSP plug-ins on multi-channel input strips.

In addition to standard plug-ins, you can also insert plugin graphs directly into the strip. When you insert a plugin graph, the signal in the strip is connected from the output of the preceding slot to the input of the inserted graph and from the output of the graph to the input of the next slot. Within the inserted graph you can do all the cool +DSP tricks that you have always been able to do, including feedback loops, mults, and so on. This allows you to build complex processing graphs and easily insert them into your production workflow.

- Direct Output Routing Point (post inserts): This pop-up menu controls the second and last available route point. It occurs "post-insert" meaing it occurs after any plugin processing from the inserts has been applied to the signal. You can choose any Physical Output or FireWire Return on the same box as the destination for this Direct Out. If you choose the "Auto" item in the menu, the mixer will automatically route to the next available output. This routing point is the appropriate one to use for "Wet" recording — meaning that in addition to using the Mobile I/O as a preamp and converter, you are also utilizing it to apply DSP processes into your record channel.

- Mute: When this button is engaged signal in the associated channel is muted at the mixer. This does not effect the signal at the direct outs. The mute button turns blue when engaged.

- Record Enable : This button enables recording of the associated channel(s) in the record panel. The Record Enable button turns red when engaged.

- <option> click will set all record enable buttons in the bus to the new value.

- Fader Gain display: Shows the channel gain level in dB. Click in the read out to edit the level numerically.

- Channel Fader: This fader allows you to adjust the channel gain level.

- Channel Meter: This meter shows the pre-fader, post insert signal level.

- Bus Name: Shows the name of the bus that this master strip is controlling. You can name this bus in the Config Mixer sheet as explained above in "Configure Mixer sheet"

-

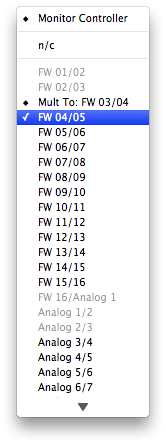

Bus Output Assign: Use this pop-up menu to select which outputs the bus is routed to. The menu that appears when you click on this control looks like the following:

Bus Output Assign Popup MenuAs you can see, there are items for the Monitor Controller, No Connection (n/c) and the available output paths. If an output path is already assigned elsewhere in the system, it will be grayed out in the menu. This ensures that you can not accidentally assign two busses to the same physical output (since only one will actually be connected). With this popup, you can control three different kinds of assignment for the bus output:

- Monitor Controller Assign: This is an on/off item in the pop-up menu. If the bus is assigned to the monitor controller (by selecting the item in the menu), there will be a diamond next to the Monitor Controller item, and the bus will appear as a pre-configured input path in the Monitor Controller. If there is no Primary output path assigned, but the bus is assigned to the Monitor Controller, "MC" will appear in the mixer UI in the popup control to indicate that the Monitor Controller is assigned

- Primary: Select an output in the Bus Output pop-up menu and it will be assigned as the primary output; this means the bus will be routed to the primary output path. The Primary output will be indicated in the menu by a checkmark. When you select another output from the list (other than the Monitor Controller item), the primary output will be changed to the path that you select and the old path will be disconnected. If there is a Primary output assigned, its name will be shown in the popup menu control in the Mixer UI. Select "n/c" to de-assign the primary output path.

- Mult: Hold the <shift> key down while selecting an output in the menu to add it to the mult list. This means that the bus will be routed to that path in addition to the Primary output and any other mult outputs. When a path has been multed to, the item in the menu is listed as "Mult to: ..." with the "..." replaced by the name of the path (as in the screen shot above). To remove a path from the mult list, select it again with the shift key held down.

- Select/Drag Strip: This area lets you select an input channel strip and move the strip either right or left within

the mixer.

- Clicking in this area will select the strip if it is not already selected.

- <command> click will toggle the selection.

- <shift> click will add strips to the current selection. All strips between the shift-clicked strip and the currently selected strip will become selected.

- Click and drag to move the selected strips left or right in the mixer.

You can click outside any strip to deselect all strips.

Routing Summary

All routing in v.5 is managed through the mixer and monitor controller. The diagram below summarizes the routing control points and what elements of the routing model they control:

v.5 Mixer Routing Connections

In the diagram above, the various colored arrows indicate different routing elements:

- The red arrows indicate input strip input assignment points. These indicate elements to route from either DAW outputs (signals sent from the computer to the Mobile I/O) or from physical inputs (Analog or Digital) to the strip’s input.

- The blue arrows indicate input strip direct routing points. These indicate elements you can route from the direct out patch points to either Firewire returns (signals sent to the computer from the Mobile I/O) or to physical outputs (Analog or Digital).

- The pink arrows indicate mix bus direct routing points. These indicate elements you can route from the direct out patch points to either Firewire returns (signals sent to the computer from the Mobile I/O) or to physical outputs (Analog or Digital). The routing point from the bottom of the strip can be used to route to multiple output points and to assign the mix bus as a source for the Monitor Controller.

- The yellow arrow indicates a mix bus assignment to the Monitor Controller. This indicates an element to route from the bus output patch point to the Monitor Controller. When assigned to the Monitor Controller, the Monitor Controller can be used to route the mix bus source to any of the defined monitor output paths.

- The green arrow indicates a mix bus assignment for an input strip. This indicates an element you can route from the input strip to a mix bus. When assigned to a mix bus the input is added to the specified mix bus.

PERSISTENT STATE MANAGEMENT

All Mobile I/O hardware has support for setting a Boot State — the configuration the hardware will use when the unit boots up. As of v.5 of the Mobile I/O software, this boot state includes the entire state of the unit including the configuration of the mixer, the router, sample rate, clocking analog I/O levels (for HW that has digital control), and +DSP configuration.

This functionality allows you to fully configure your hardware and “pour” a complete digital signal processing engine into the HW for instant-on processing.

To configure the Boot State for your Mobile I/O:

- First, attach the Mobile I/O to the computer and start up MIO Console.

- Use MIO Console to configure the box. Set up all aspects that you care about. Once you have the configuration as you like it, you are ready to save the snapshot.

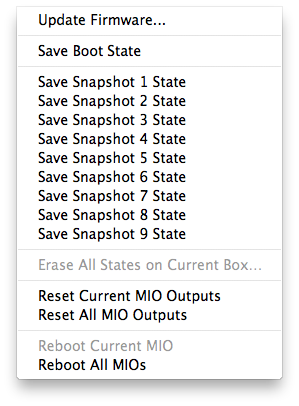

- Choose the “Save Boot State” command from the “Utilities” Menu

The ULN-2 hardware extends the Boot State and adds support for Persistent State Snapshots. There are 10 snapshot slots in the ULN-2 that are recallable from the controls on the ULN-2 front panel. Each Persistent State Snapshot contains a complete description of the state of the box, including Sample Rate, Clock Source, Digital input source, Sample Rate Converter Enable, Patchbay routing, Mixer Configuration, Levels and +DSP configuration and routing. In other words, a snapshot saves every aspect of the configuration of the ULN-2.

The first snapshot slot is special as it is used by the unit to configure the hardware and the routing when the ULN-2 starts up. The other 9 slots are available for storing alternate configurations that can be selected “on the fly” after the ULN-2 is up and running.

When a computer is attached to the ULN-2, the front-panel controls to select snapshots are locked-out since the computer is actively controlling the configuration of the box.